INOMECH s.r.o.

office and mail address

Martina Koláře 2118

390 02 Tábor

Czech Republic

GPS: 49°24'27.345"N, 14°40'26.165"E

phone : +420 725 872 201

e-mail: inomech@inomech.com

Since the beginning of our being at the market of the Industrial Process Automation we offer specific and individually fitted solutions. Wide range of references from various industrial branches helped us to become the sought after solver of those assignements that are too complicated for other automation companies.

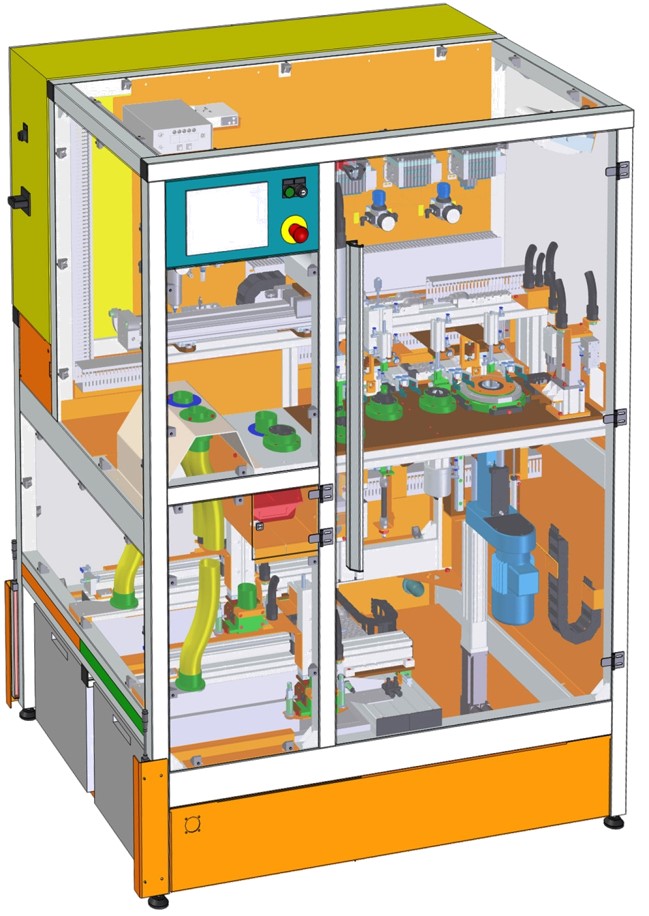

For our customers we developed and supplied range of mounting and testing devices from simple ones to fully automated machines with advanced electronics and camera systems. Inomech s.r.o developed machines capable of self-calibration and accurate pressure and flow measurements for tightness tests inserted into our machines.

We take the use of safety elements for granted in order to maximally ensure safety operation of the machine. Latelly we mostly use the integrated modular security in control systems. Our machines are designed to maximise power, efectivity, safety and quality but also with the human to machine interaction taken into account. In order to achieve easy and safety operation, setting and service, the ergonomics comes into business and is neccessary part of our proposals. Comfort touch screens are used for visualisation of the manufacturing process, setting and the own machine operation thus becomes intuitive and as simple as if you were using your smartphone or tablet. Long distance diagnostics and control saves your time, money and brings you a quick reaction in cases of any extra requirements or failure.

There is lot more to say. Do not hesitate to contact us, come and visit us or just pop us a message and we will come to your site to present ourselves.

Examples of finished products

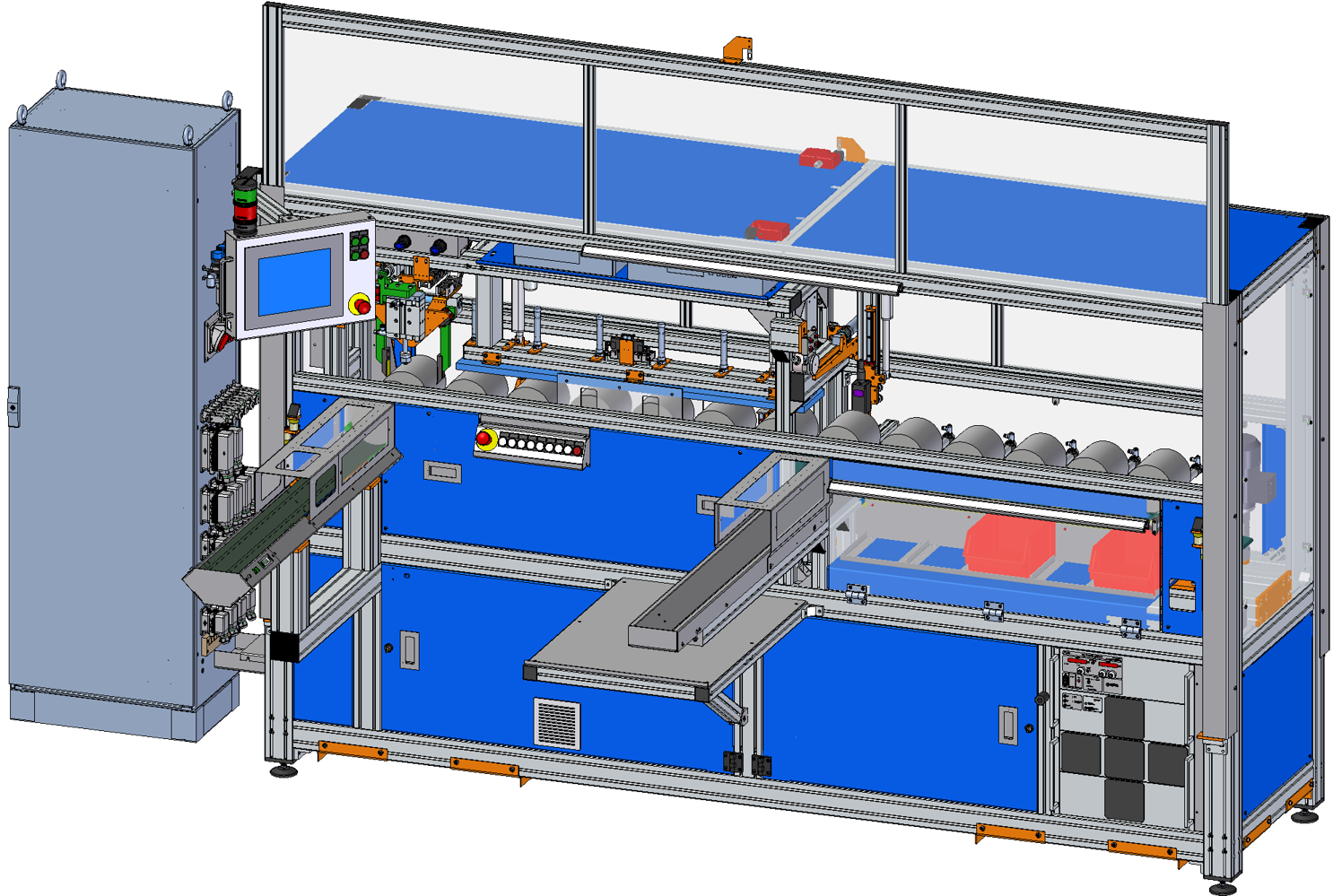

Bearing Cap Honing - bore tolerance 0,02 mm, honing depth control double checked by depth measurement with tolerance 0,1mm, concentricity of the honed bore with the initial diameter 0,025 mm, camera checked neatness of the honed bore.

Bearing Cap Honing - bore tolerance 0,02 mm, honing depth control double checked by depth measurement with tolerance 0,1mm, concentricity of the honed bore with the initial diameter 0,025 mm, camera checked neatness of the honed bore.

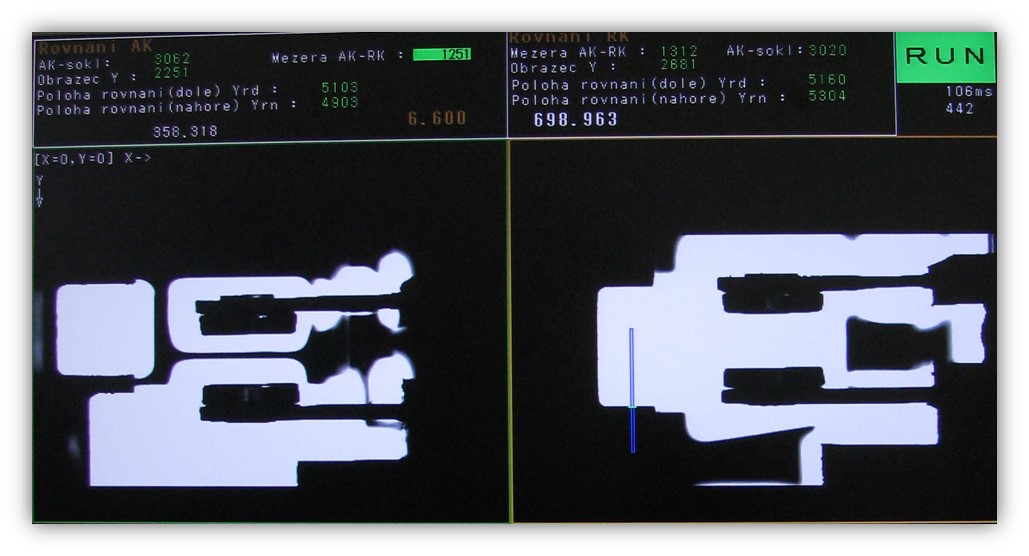

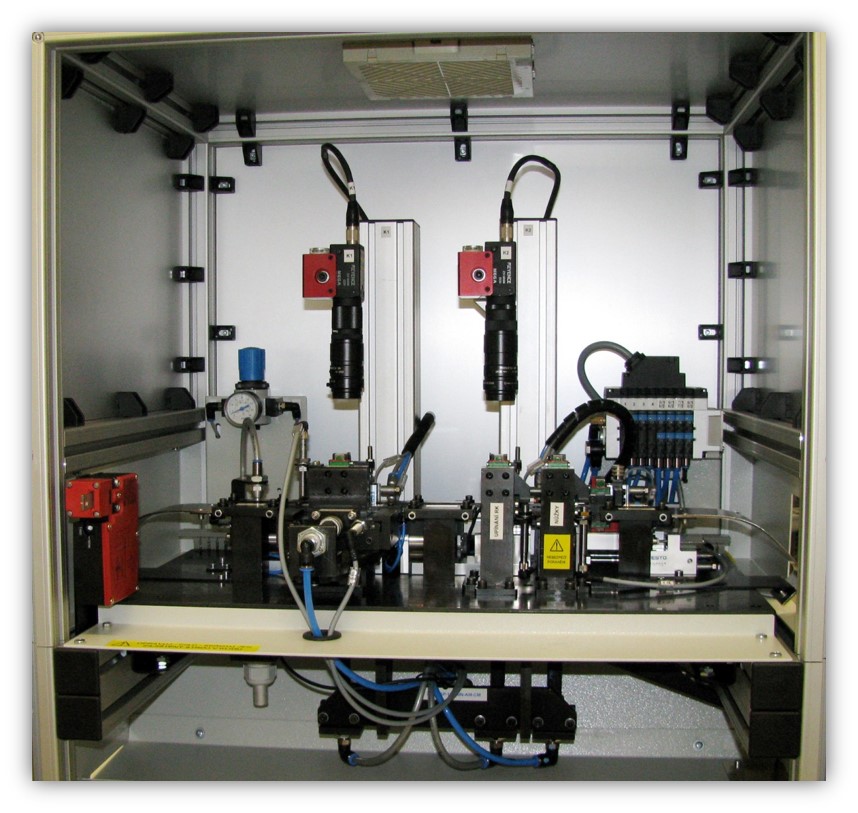

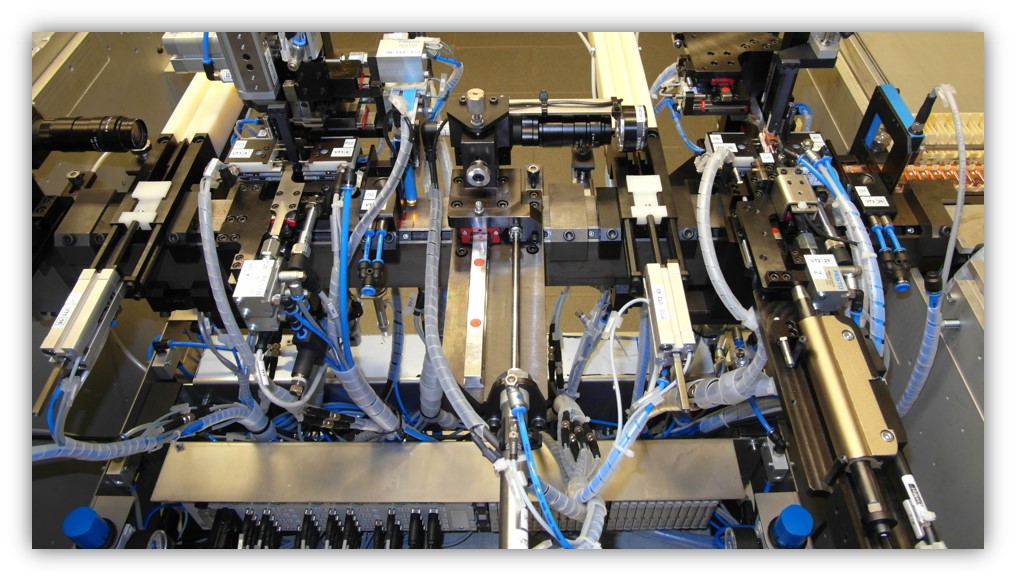

Relay Contact Adjusment - repeated accuracy by camera measuring ±0,0025 mm. Adaptive strategy of bending. „Voice Coil“ traction of adjusting hammers. Accuracy of contacts positions to each other before adjustment ±0,15mm, adjusted ±0,02 mm.

Relay Contact Adjusment - repeated accuracy by camera measuring ±0,0025 mm. Adaptive strategy of bending. „Voice Coil“ traction of adjusting hammers. Accuracy of contacts positions to each other before adjustment ±0,15mm, adjusted ±0,02 mm.

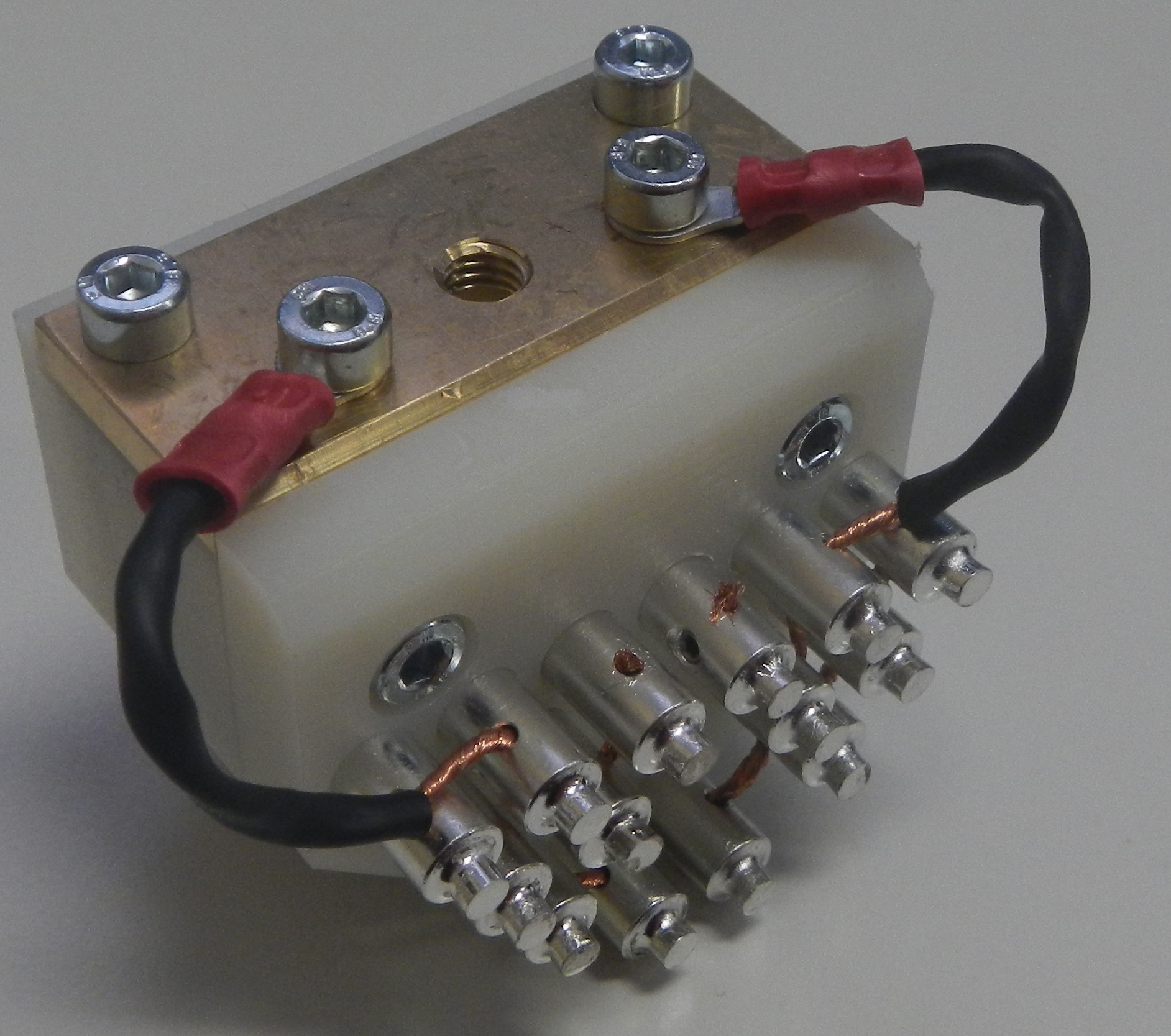

Axial Lead Capacitor Testing - voltage testing by the maximum voltage of 12,5kV/800mA DC, measuring of electrical quantities (capacitance, dissipation factor, residual current), automatic sorting, capacitor marking, measured values archivation, capacitor diameter/length in range of 40-150/25-160mm.

Axial Lead Capacitor Testing - voltage testing by the maximum voltage of 12,5kV/800mA DC, measuring of electrical quantities (capacitance, dissipation factor, residual current), automatic sorting, capacitor marking, measured values archivation, capacitor diameter/length in range of 40-150/25-160mm.

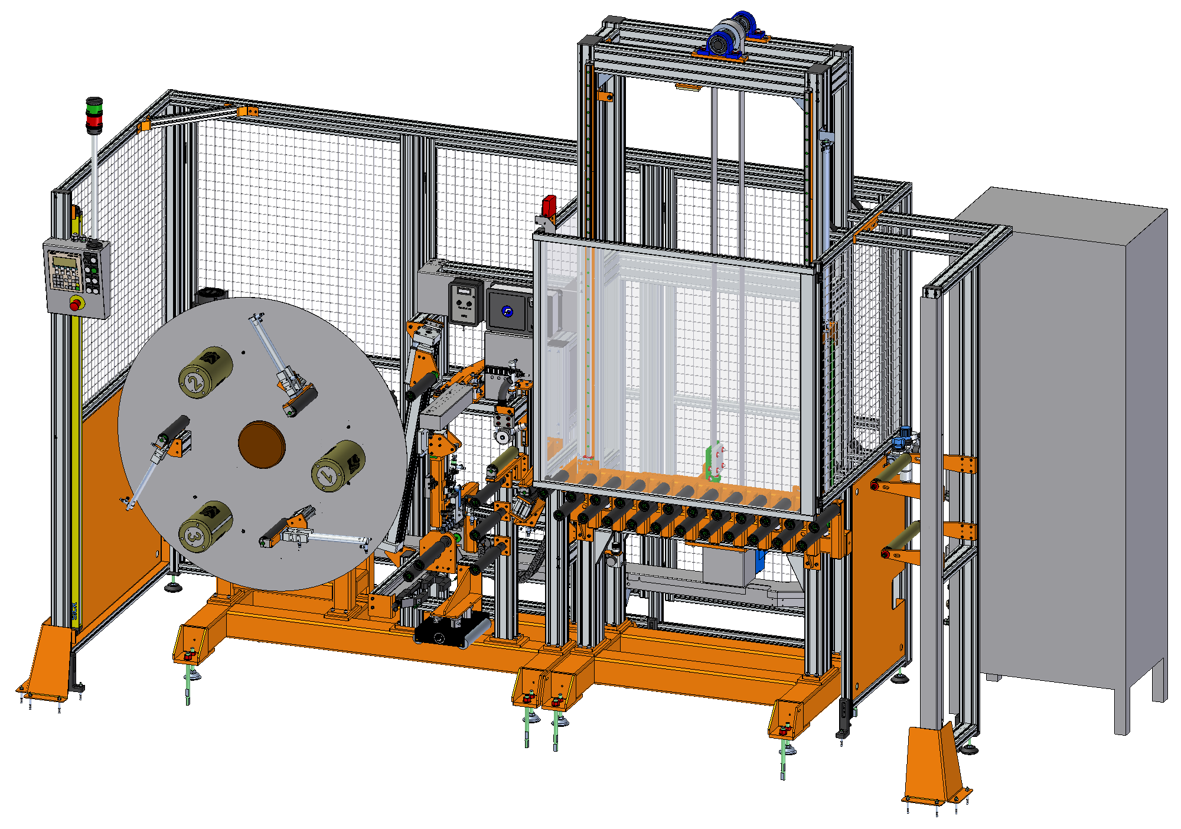

Triple-drum Automatic Winder With Compensator - winding of produced meat casings, automatic cutting and change of coils, winding speed up to 200m/min.

Triple-drum Automatic Winder With Compensator - winding of produced meat casings, automatic cutting and change of coils, winding speed up to 200m/min.

Relay Adjustment - relay contacts position adjusting according to mechanical and electrical properties, measuring of concurrent position, relay voltage characteristics, adjusting according to measured values.

Relay Adjustment - relay contacts position adjusting according to mechanical and electrical properties, measuring of concurrent position, relay voltage characteristics, adjusting according to measured values.

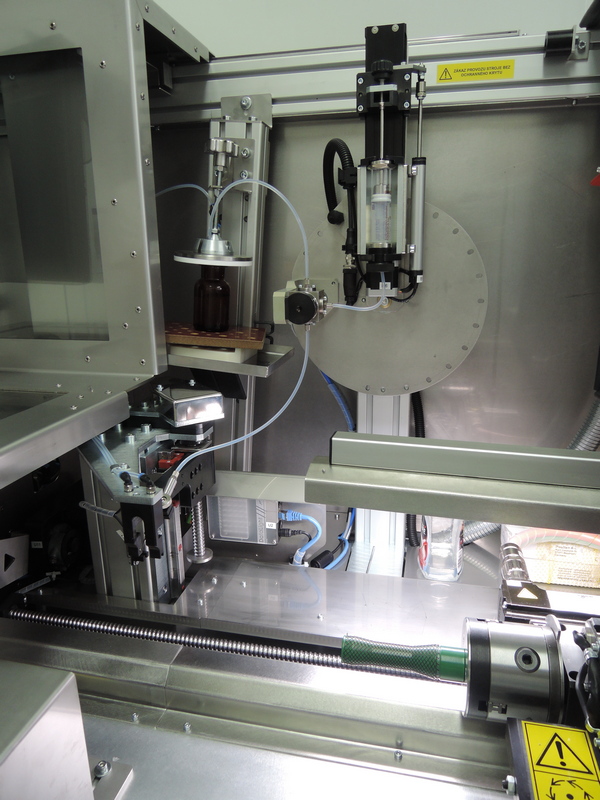

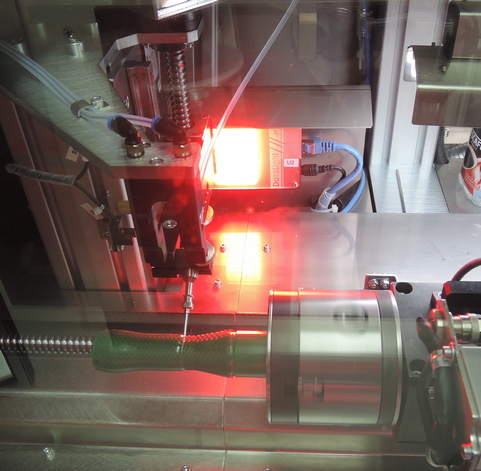

Stent Coating (medical product) - coating the stent surface by a unique mixture, accurate dosage of the mixture - units ml/min, drying, camera controlled position of the coating needle according to the stent shape

Stent Coating (medical product) - coating the stent surface by a unique mixture, accurate dosage of the mixture - units ml/min, drying, camera controlled position of the coating needle according to the stent shape

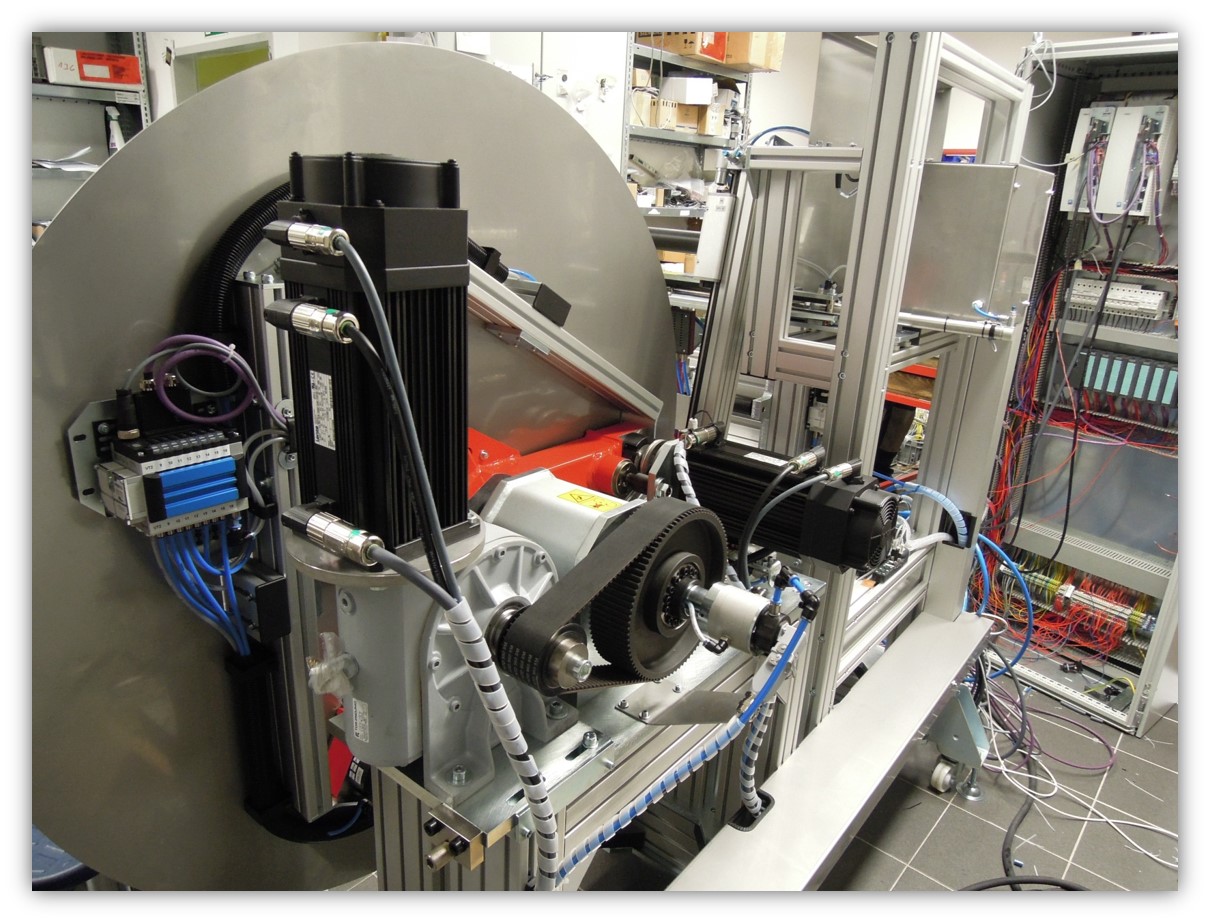

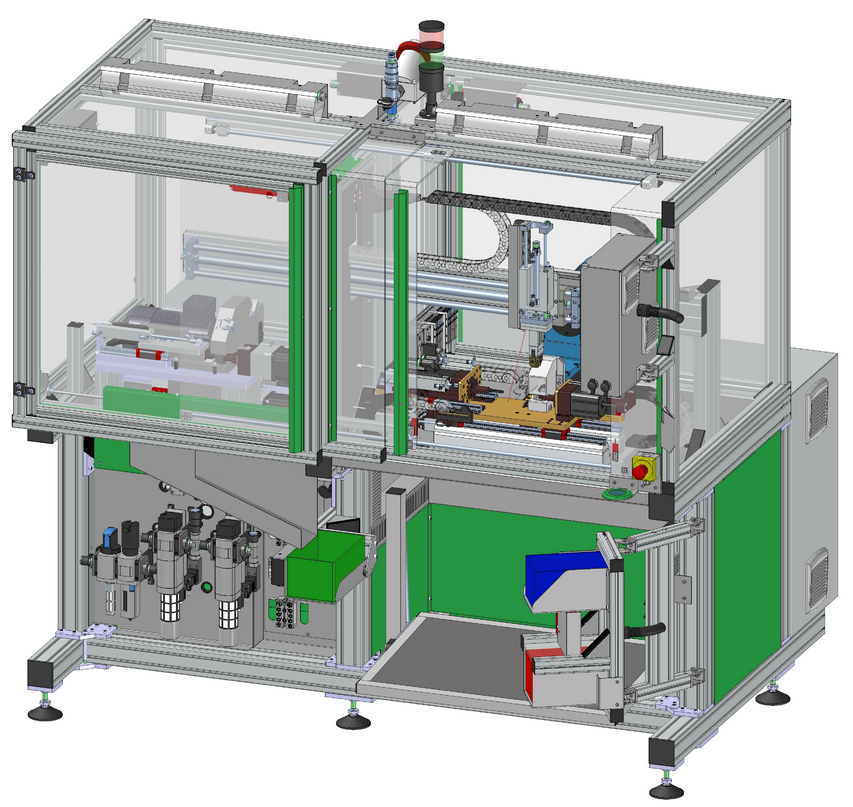

Machining and Brushing of Cams - cams for switches made out of a cylindrical semi-finished product - polycarbonate, automatic adjusment according to required type of final product, type detection using Camera Barcode Reader, adaptive brush adjustment as it wears, accurate turning axis with two servomotors, impurity vacuuming, machine cooling, G-code ready control system, G-code generating for every product in the database, more than 8000 product types.

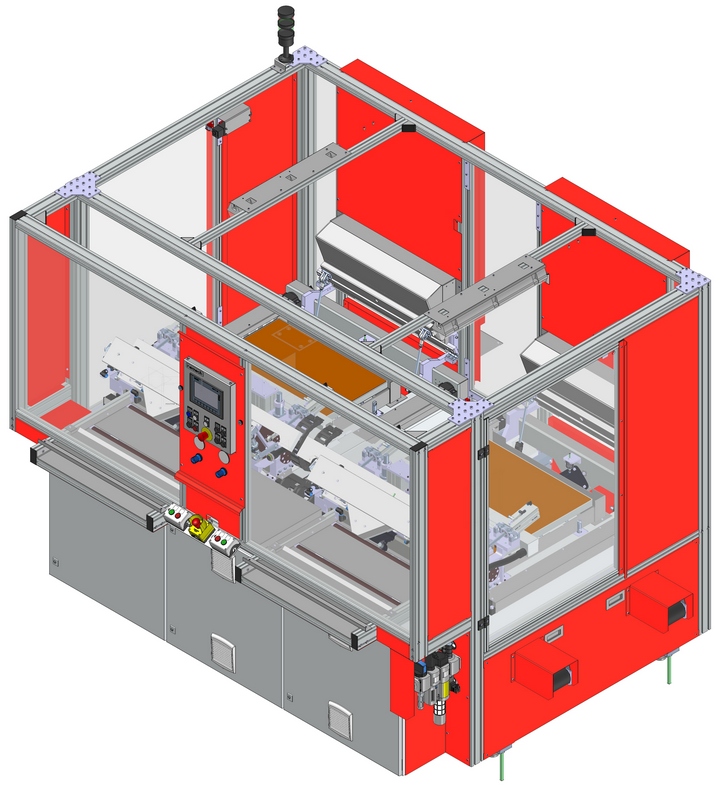

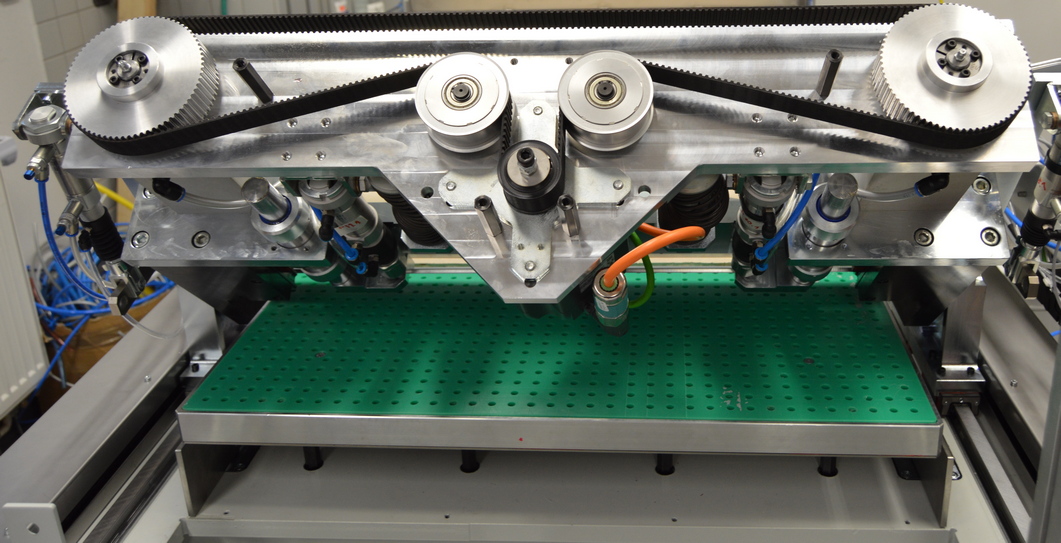

Rubber Cutter - rubber cutting with vertical or 45° angle of cut. Semi-finished product in shapes of rubber sheets 700 x 700 mm and thickness 8 to 16 mm. Diamensions of final cuts are in range of 26x18,5 mm to 54x48 mm.

Rubber Cutter - rubber cutting with vertical or 45° angle of cut. Semi-finished product in shapes of rubber sheets 700 x 700 mm and thickness 8 to 16 mm. Diamensions of final cuts are in range of 26x18,5 mm to 54x48 mm.

YOUR INNOVATIVE SOLUTIONS

|

Many years of experience from achieving objectives in fields of assembly machines, machine tools, mono-purpose and special devices and closely cooperate with CTU in Prague. |

We try to offer services at high quality level for wide range of customers. At the market we would like to be differentiated by high quality and reliability of our services and customer care. |